Aerodynamics and Aeroacoustics

With strong industrial support and the non-profit cost center model, the Stability Wind Tunnel has been able to build a formidable array of state of the art capabilities and instrumentation for wind turbine blade testing. This includes computerized airfoil-mounting systems, airfoil flow control, velocity and turbulence sensing using optical and non-optical systems, airfoil surface pressure scanning, wake scanning, 3-D traversing, computerized flow visualization systems, and surface pressure fluctuation measurement systems. Prof. Burdisso and his former graduate student Dr. Patricio Ravetta developed microphone phased array technology critical for the aeroacoustic measurements of wind turbine blades in the Stability Wind Tunnel Hybrid Aerodynamic Test Section. Virginia Tech has phased array acoustic instrumentation and software that includes systems with 63 and 117-channels. In collaboration with AVEC Incorporated, these phased array systems have been and are being used to perform numerous acoustic studies looking particularly at acoustic source identification, trailing edge modifications to reduce noise, extrapolating acoustic behavior to full scale conditions, correlating acoustic behavior with loading, and documenting acoustic characteristics at realistic aerodynamic conditions.

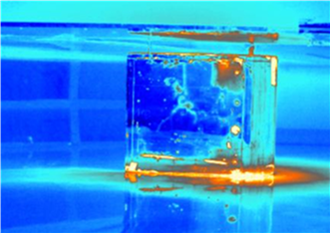

Currently under development are systems for infrared transition detection, global optical boundary layer measurement, and stereoscopic camera system for boundary condition definition. Through the machine shop of the Department of Aerospace and Ocean Engineering (AOE), the facility has cutting edge design, fabrication and instrumentation capabilities for wind turbine blade-section models. Find more information.

As part of the wind tunnel’s mission these brand new capabilities are deliberately and regularly placed in the hands of Virginia Tech’s undergraduate students. The facility hosts required laboratory courses in AOE, Mechanical Engineering (ME) and Engineering Science and Mechanics. In recent years these laboratories have been structured as wind turbine tests, giving our students state-of-the-art experience in the science of wind energy. The goal is to expand this educational component and to move towards industrial sponsorship and participation in these educational experiences.